![]()

The group of MOVPE epitaxy and investigations of the properties of nano-heterostructures based on group III nitrides

.Equipment for epitaxial growth by the MOVPE method

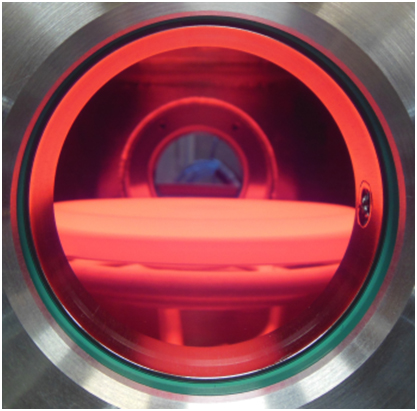

The Dragon-125 MOVPE system

The metalorganic vapour-phase epitaxy setup Dragon-125 of its own unique design has been completely developed and produced by the employees of the MOVPE epitaxy group. Launched into operation in 2014 the Dragon-125 setup is assigned for the experimental and small-scale production of the heterostructures and semiconductor devices based on the AlInGaN materials system.

The setup has inductively heated horizontal reactor with rotating susceptor suitable for either three substrates with diameter of 2" or one with diameter of 3" or with a diameter of 100 mm. The Dragon-125 MOVPE system equipped with three-beam in-situ optical reflectometry system for reflection and curvature of the substrate measurements allows to realize a wide range of the epitaxial growth parameters: growth temperature up to 1250 °C, reactor pressure in the range from 70 to 1600 mbar (which is above the atmospheric pressure).

External view of the Dragon-125 MOVPE system

|

|

The main features of the Dragon-125 MOVPE system:

Compact size (less than 3x1 m2).

Water cooled horizontal stainless steel reactor.

Induction heating of the reactor up to 1200 °С.

Multi-zone pyrometric control of the growth temperature.

Reactor pressure in the range from 70 to 1600 mbar (which is above the atmospheric).

Special injector for epitaxial process control and suppression of the parasitic reactions.

8 lines for the MO compounds + 2 reserved lines

Graphite susceptor with rotation system suitable for three substrates with diameter of 2" or one with diameter of 3" or with a diameter of 100 mm.

Three-beam in-situ optical reflectometry system for growth rate and curvature of the substrate control (curvature resolution - 2-3 km-1, reflection signal noise of 0.02%, precise positioning with resolution of <1mm)

The possibility to shorten of the epitaxial growth process duration of the semiconductor device structures (light-emitting diodes and field-effect transistors) by increasing of the growth rate and by reducing of the transient stages duration.

Developing possibilities of new promising technologies for epitaxial deposition of graphene layers on III-N based heterostructures and obtaining of insulating Al(GaN) layers doped with carbon and Fe atoms.

Specially designed MOPVE setup control system, which allows to automatically eptaxially growth of heterostructures of any complexity without limitations by the growth process durations with real time growth parameters registration.